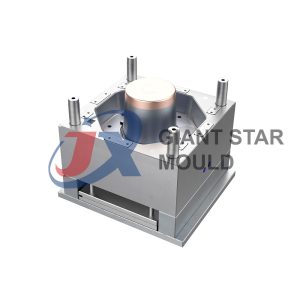

Paint Bucket Mould 01

Paint Bucket Mould 01

Making a paint bucket mold involves several steps and requires precision to ensure the final product meets quality standards. Here’s a basic outline of the process:

Design: The first step is to design the mold using CAD (Computer-Aided Design) software. This design includes all the details of the paint bucket, such as its shape, size, handles, and any logos or markings.

Material Selection: Select the appropriate material for the mold based on factors like the expected production volume, type of plastic used for the buckets, and the required durability of the mold. Typically, molds are made from metals like steel or aluminum.

Machining: Once the design is finalized, the mold is created through machining processes such as CNC milling or EDM (Electrical Discharge Machining). These processes shape the metal block into the desired mold form, following the specifications from the CAD design.

Surface Treatment: After machining, the mold’s surfaces may undergo treatments like polishing or coating to ensure a smooth finish and to prolong the mold’s lifespan.

Assembly: If the mold consists of multiple parts, they are assembled together carefully to form the complete mold structure. This may involve techniques like welding or bolting.

Testing: Before mass production begins, the mold undergoes testing to ensure it produces paint buckets that meet quality standards. Testing may include trial production runs, inspecting sample buckets for defects, and making any necessary adjustments to the mold.

Production: Once the mold passes testing, it’s ready for use in mass production. Molten plastic is injected into the mold cavity, where it cools and solidifies to form the paint bucket shape. The mold is then opened, and the finished bucket is ejected.

Maintenance: Regular maintenance is essential to keep the mold in good condition and ensure consistent quality of the paint buckets. This includes cleaning, lubricating moving parts, and repairing any wear or damage that occurs during production.

Throughout the entire process, attention to detail and precision are critical to producing high-quality paint bucket molds that meet industry standards.

Related products

-

Plastic Bucket Mould 01

Read more -

Plastic Basin Mould 09

Read more -

Paint Bucket Mould 11

Read more -

Paint Bucket Mould 09

Read more -

Paint Bucket Mould 07

Read more -

Paint Bucket Mould 06

Read more -

Paint Bucket Mould 02

Read more -

Flow Pot Mould 10

Read more -

Flow Pot Mould 09

Read more -

Flow Pot Mould 08

Read more -

Flow Pot Mould 04

Read more -

Flow Pot Mould 03

Read more