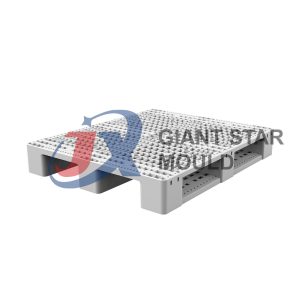

Pallet Mould 04

Pallet Mould 04

The manufacturing process of plastic pallet mold is a complex and delicate process, which involves multiple links, including material selection, design, processing, assembly and testing. Below, I will introduce these steps to you in detail.

First of all, material selection is the first step in manufacturing plastic pallet molds. The choice of mold material directly determines the life, precision and cost of the mold. Commonly used mold materials are carbon tool steel, alloy tool steel, high-speed steel, stainless steel, etc. When selecting materials, factors such as the mold’s use environment, workload, and production batch need to be considered to ensure that the mold can meet production needs.

Next is the design stage. The design stage is a key link in the entire manufacturing process, which determines the structure, size and precision of the mold. When designing, it is necessary to use computer-aided design software such as CAD and CAM to draw the three-dimensional model and processing drawings of the mold according to the product shape, size and precision requirements. At the same time, auxiliary functions such as exhaust, cooling, and guiding of the mold also need to be considered to ensure that the mold can work smoothly and stably during use.

Then comes the processing stage. The processing stage is the process of converting the design drawings into actual molds. During the processing, various machine tools and tools, such as milling machines, grinders, and EDM machines, are needed to cut, grind, and process the mold materials. During the processing, it is necessary to strictly follow the design drawings and process requirements to ensure the dimensional accuracy and surface quality of the mold.

Next is the assembly stage. The assembly stage is the process of assembling various parts into a complete mold. During assembly, it is necessary to ensure that the matching accuracy and clearance between the various parts meet the requirements, and necessary debugging and corrections are required to ensure that the mold can work properly.

Finally, there is the testing stage. The testing stage is the process of testing and evaluating the performance of the mold. During the test, it is necessary to use the actual product for trial mold to check whether the molding effect, dimensional accuracy, and surface quality of the mold meet the requirements. If problems are found, they need to be repaired and adjusted in time to ensure that the mold can be put into use normally.

In addition to the above main links, the following points should be noted when manufacturing plastic pallet molds:

Ensure that the working environment is clean and orderly to avoid dust and debris from polluting and damaging the mold.

Regularly maintain and maintain machine tools and tools to ensure their normal operation and stable accuracy.

Strictly abide by the safety operating procedures to ensure the safety of personnel and equipment.

In short, the manufacturing process of plastic pallet molds is a complex and delicate process that requires close cooperation and strict control of all links. Only in this way can high-quality and high-efficiency molds be manufactured to meet production needs.

Related products

-

Pallet Mould 27

Read more -

Pallet Mould 26

Read more -

Pallet Mould 24

Read more -

Pallet Mould 23

Read more -

Pallet Mould 21

Read more -

Pallet Mould 17

Read more -

Pallet Mould 16

Read more -

Pallet Mould 09

Read more -

Pallet Mould 10

Read more -

Pallet Mould 06

Read more -

Pallet Mould 02

Read more -

Pallet Mould 01

Read more